PUR, PIR BOARDS

Polyisocyanurate foam (PIR)

- Polyisocyanurate is made in the same way as polyurethane, but the ratio between the components and the type of additives is usually different, to produce a polymer containing chemical bonds with a higher temperature resistance.

- The increase in the decomposition temperature depends entirely on the concentration of these bonds and on the aromatic content.

- Process control factors are more critical than with PUR.

- The smoke and decomposition products are similar to PUR.

PIR typically has an MDI/polyol ratio, also called its index (based on isocyanate/polyol stoichiometry to produce urethane alone), higher than 180. By comparison PUR indices are normally around 100. As the index increases material stiffness the brittleness also increases, although the correlation is not linear. Depending on the product application greater stiffness, chemical and/or thermal stability may be desirable. As such PIR manufacturers can offer multiple products with identical densities but different indices to achieve optimal end use performance.

- The reaction of MDI and polyol takes place at higher temperatures compared with the reaction temperature for the manufacture of PUR.

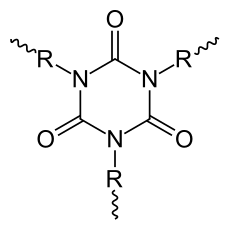

- At these elevated temperatures and in the presence of specific catalysts, MDI will first react with itself, producing a stiff, ring molecule, which is a reactive intermediate (a tri-isocyanate isocyanurate compound). Remaining MDI and the tri-isocyanate react with polyol to form a complex poly (urethane-isocyanurate) polymer, which is foamed in the presence of a suitable blowing agent. This isocyanurate polymer has a relatively strong molecular structure, because of the combination of strong chemical bonds, the ring structure of isocyanurate and high cross link density, each contributing to the greater stiffness than found in comparable polyurethanes. The greater bond strength also means these are more difficult to break, and as a result a PIR foam is chemically and thermally more stable: breakdown of isocyanurate bonds is reported to start above 200 °C, compared with urethane at 100 to 110 °C.

Polyurethane (PUR)

- is a polymercomposed of organicunits joined by carbamate (urethane) links. While most polyurethanes are thermosetting polymers that do not melt when heated, thermoplastic polyurethanes are also available.

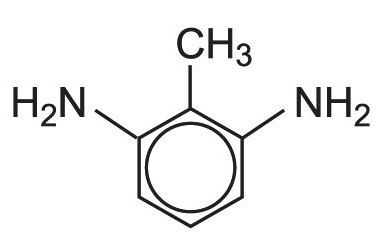

- Polyurethane polymers are traditionally and most commonly formed by reacting a mdi- or poly-isocyanatewith a polyol. Both the isocyanates and polyols used to make polyurethanes contain, on average, two or more functional groupsper molecule.

Production

- Polyurethanes are produced by mixing two or more liquid streams.

- The polyol stream contains catalysts, surfactants, blowing agents and so on.

- The two components are referred to as a polyurethane system, or simply a system.

- Polyurethane can be made in a variety of densities and hardness’s by varying the isocyanate, polyol or additives.

Most important PU Physical properties:

- Thermal insulation.

- Hardness.

- Tensile strength.

- Tear strength.

- Compression strength.

Description:

- Overall density of insulation foam 42 kg/m3

- Hardness.

- Core density 38-42kg/m3

- K- Value 018 W/m.K

- Compressive strength of insulation 21 N/mm2

- Closed cell contains 97%

- Water vapor transmission 4%

- Water absorbent 9 Vol. %

- Fire Strength DIN to the insulation DIN 4105, B3

- Weight of the Panel 9-13 kg/m2

Fire behavior (Terms & definition)

- Fire retardant A substance added, or a treatment applied to, a material to suppress, significantly reduce or delay the combustion of the material.

- Non-combustible Not capable of undergoing combustion under specified test conditions.

- Reaction to fire The fundamental behavior of a material in fire described in terms of rate of heat release, Potential energy release, surface burning, and smoke release, tendency to produce burning droplets or particles.

- Resistance to fire Fire resistance of a building element is defined as the time (measured since the heating period starts) until the specimen does not satisfy any more its functional properties.