Wall Panels

What is Sandwich Panel?

Sandwich panel is a system that protects the buildings from external factors and provides the most convenient and economical solution for them to have a powerful stand. As modern, light and durable construction elements, sandwich panels are used to clad external walls of the buildings as well as achieving insulated internal walls and cold storages.

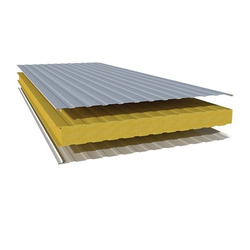

Sandwich panels, protecting you against the external factors on all sides of your building, are produced by filling in a thick and low density insulation material between two thin and high density metal surfaces. These ready-assembled building elements, which have a high load carrying capacity despite their own low weight, are produced on continuous and discontinuous lines.

Different insulation materials should be chosen according to the needs of the buildings. Sandwich panel production is made in all insulation types including PUR, PIR, Mineral Wool and EPS. You can decide which type of sandwich panel is suitable for your building or project by taking into consideration the thermal, humidity, sound insulation and fire resistance needs of thereof.

Sandwich panels are generally used in industrial facilities, commercial buildings, cold storages, residential buildings, power plants as well as buildings for agricultural and husbandry.

Sandwich Panel Advantages

- Fast and Easy Installation

- Perfect Thermal Insulation

- Investment Economy

- Aesthetic Appearance of Your Buildings

- Air and Water Tightness

Sandwich Panel Selection Guide

Selecting the insulation core in accordance with the need of your building positively affects the performance you will obtain from the sandwich panel.

Polyurethane (PUR)

Polyurethane is the rigid foam formed by mixture of main components ‘polyol and isocyanate’ with catalyst materials under high pressure and special production conditions. Ensuring superior thermal insulation by its closed cell structure, polyurethane has high dimensional stability, and does not absorb water. It does not create bacteria. Its mechanical performance is very high thanks to its high compressive strength.

Polyurethane (PIR)

A new macromolecular structure called polyisocyanurate is formed when the main components of the polyurethane foam chemically react at different mixture quantities. Polyisocyanurate rigid foam is the version of polyurethane with higher, enhanced fire resistance performance due to the difference in its structure. In case of a fire, the formation of smoke is very low when compared to polyurethane.

Sandwich Panel Coating and Color Selection

Inner and outer sheet features of sandwich panels shall be determined according to the environmental conditions your building may be exposed to.

The outer sheet of the sandwich panels shall be resistant to the temperature changes caused by atmospheric pollution, wind, sun, and contact with ultraviolet rays, as well as chemical and physical effects.

Inner sheet, on the other hand, is lower in temperature when compared to the outer sheet thanks to the insulation core of the sandwich panel. Therefore, the inner sheet is not affected by atmospheric conditions and UV rays. However, inner sheets may face different chemical and physical effects arising from the indoors environmental conditions of your building, such as condensation and chemical gases.

The metal substratum, coating type and color to be used on the sandwich panel surfaces shall be chosen according to the function of your building, the environmental conditions it will be exposed to, and aesthetical and economic needs.

Metal surface alternatives of sandwich panels:

- Preprinted sheet obtained by coating the hot dipped galvanized or galvalume sheet

- Natural or preprinted aluminum and stainless steel.

- Gypsum and cement board sheets

Preprinted Galvanized Steel Coating Layers

The sheet galvanized by being coated with a zinc layer between 60 gr/m2 - 275 gr/m2 by using the hot dipping method is produced on highly automated continuous lines called coil coating.

Coating Colors

RAL color chart is referenced while determining the colors in preprinted galvanized sheet production..

Coating Type And Specification

StyroQ offers various coating alternatives for you to use for sandwich panels based on the location and needs of your building.

Polyester Coatings

Thanks to their variety of color and gloss options and being an economic solution, the usage areas of polyester coatings are very wide. Moreover, polyester coatings are highly resistant towards flexibility, abrasion, corrosion, humidity, and impact.

PVDF Coatings

The strongest feature of PVDF coatings is that their resistance towards color, gloss, chalking, and many chemicals is high. Moreover, their resistance towards impact and abrasion, as well as their flexibility is very good. On the other hand, PVDF coatings are less scratch resistant, and their color and gloss options are limited when compared to polyester coatings.

Polyurethane Coatings

Polyurethane coatings become highly scratch and friction resistant with polyamide reinforcement, they can be applied in flat and patterned forms. They are highly corrosion, color and gloss resistant, and highly shapeable.

PVC Films

PVC films are used in indoor or outdoor applications as laminated on aluminum or galvanized steel surfaces. They are particularly preferred in cold storage applications with their high resistance to corrosion and humidity. Depending on the place and purpose of use.