Pipe Insulation

By virtue of Expanded Polystyrene (EPS) pipe section’s physical and thermal properties, it is widely used as an insulating material to insulate the chilled water pipes and ducts thus prevents condensation & protects against freezing.

Besides, EPS pipe sections are extensively used to insulate the Refrigerant pipes and other utility lines especially in MEP (Mechanical, Electrical and Plumbing), and also HVAC (heating ventilation and air conditioning systems) projects to prevent the total system from refrigeration losses and condensation. Generally, working efficiency of the Refrigerant equipment will obviously depend on the quality and reliability of the Insulation material which is used. In such circumstances EPS pipe insulation dictates that it is nothing but the best insulation material.

- Dimensionally stable

- High Thermal Insulation

- Light-Weight

- Zero Water Absorption

For over 50 years, EPS Pipe and Duct insulation secured a firm position for itself as an insulating material in the chemical factories, textile and paper mills, ice factories, dairies, breweries, heating ventilation and air conditioning systems (HVAC) and all kinds of MEP (Mechanical, Electrical and Plumbing) activities.

Benefits of EPS pipe sections for Insulation

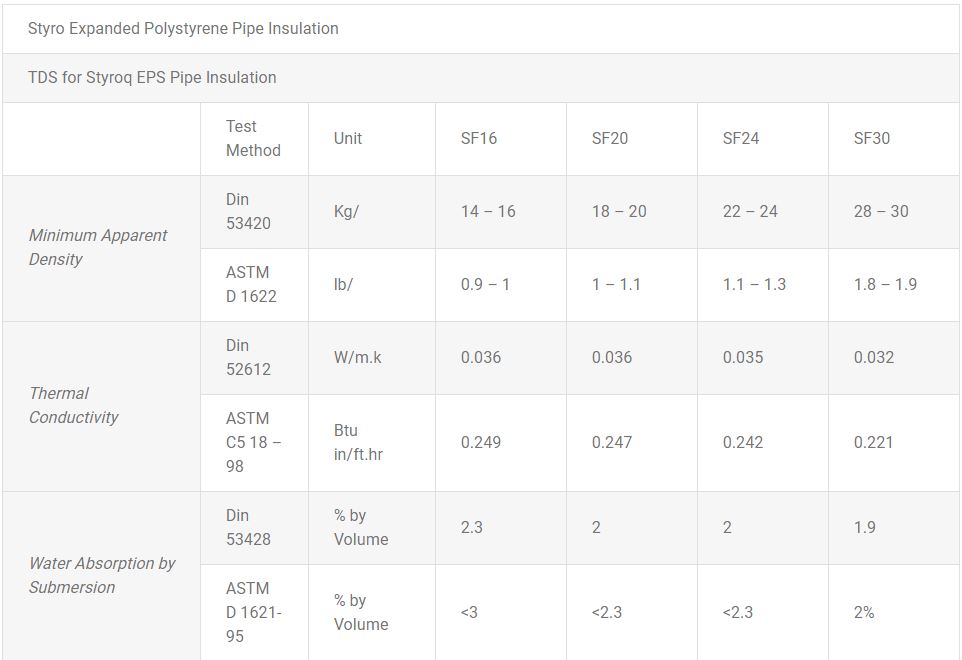

From engineering and economic aspects, it is often advisable or even essential to protect pipelines from heat losses and condensations. Low thermal conductivity, low permeability to water vapor, low water absorption, high dimensional stability, good mechanical strength and protection from fire hazards are the aspects which will constitute the ideal insulating material. EPS – expanded polystyrene pipe section incorporates all these aspects well and is therefore particularly effective. EPS pipe sections are 95% closed cell structure which ensures better insulation.

EPS pipe section does not support mold, fungus infection or pest life and are unaffected by any bacteria, making it the ideal choice for pipe and duct insulation operating in areas such as food processing etc… where the highest degree of hygiene is required.

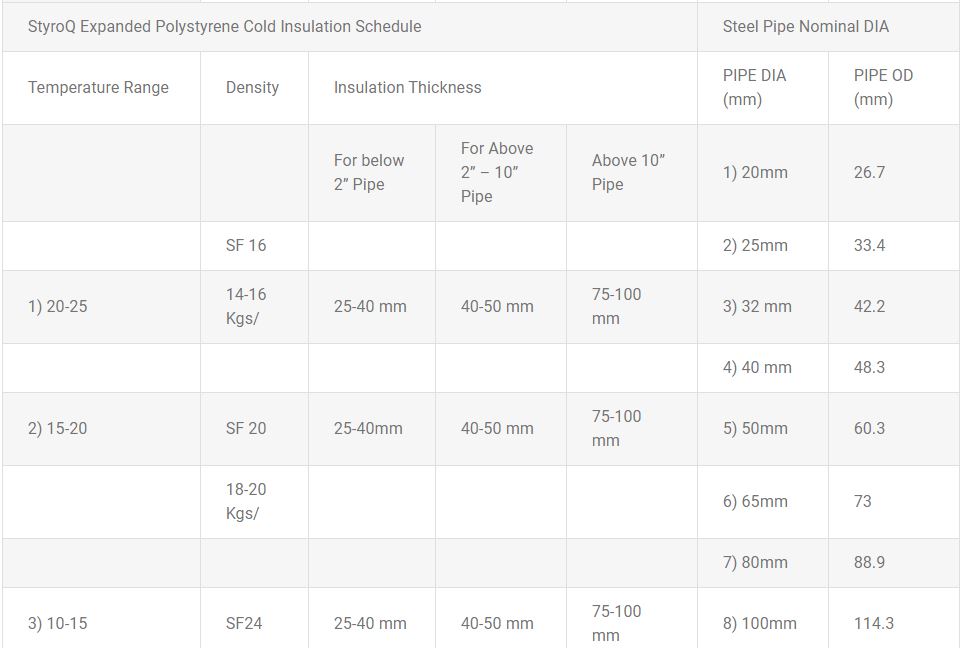

EPS pipe sections are manufactured on “Made to Order Basis” according to the customer’s sizes and specifications. It can be cut with Shiplap joints and Tongue & Groove arrangements with the aid of High-Tech CAD / CAM – CNC Machines. Normally EPS Pipe sections are cut into two halves with readily wrapped FRK facing (Foil Reinforced Kraft paper) in order to simplify the installation works at the sites.